We have recently introduced a new class of cavity resonators and filters, termed distributed resonators [1] and [2]. The distributed resonator allows a major reduction in the resonator profile while maintaining an excellent electrical performance. In [1], an individual distributed resonator consists of a number of low-profile resonant posts arranged in a grid, where the resonant posts on the vertical and horizontal axes of the grid mainly couple to their immediate neighbors. The substantial reduction in the filter profile, comes – to a degree – at the price of the footprint, mainly due to the fact that the individual distributed resonator consists of a number of resonant posts. In our previous contribution of [2], the concept of [1] is somewhat further generalized, where it was suggested that a resonant element of [1] can itself be made in a distributed form. In both [1] and [2], the resonators and filters are made to operate in the air.

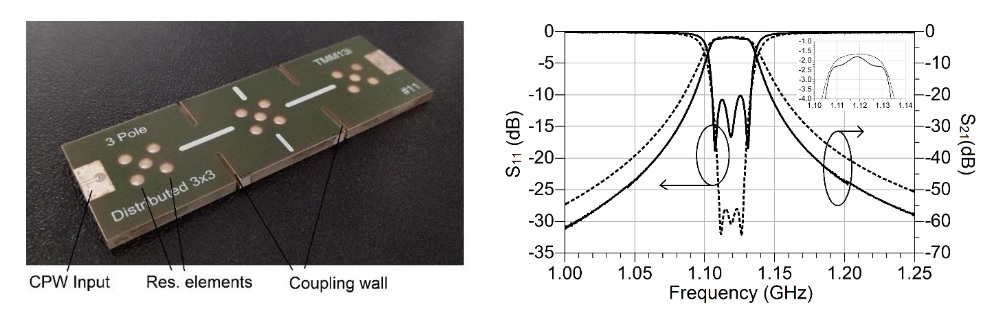

In this paper, a new family of ceramic resonators and filters is introduced. The proposed resonators are enabled by the integration of distributed resonators into standard Printed Circuit Board (PCB) substrates. This integration caters for not only a tremendous reduction in the resonator profile, but it also enables utilization of the unused PCB real estate. As an example of the feasibility of the proposed idea, a 3-pole filter based on 3-by-3 distributed resonant elements was designed and fabricated, Fig. 1. The filter was made to operate at a frequency of 1.12 GHz with a bandwidth of 20 MHz. The substrate used for this filer has the dielectric permittivity of 12.85 and a loss tangent of 0.0019. The measured results show a good agreement with simulations, Fig.1.

- S. Bulja and M. Gimersky, “Low-Profile Distributed Cavity Resonators and Filters,” IEEE Trans. Microw. Theory Techn., vol. 65 issue 10, pp. 3769-3779, 2017.

- S. Bulja and D. Kozlov, “Split-distributed resonators and filters”, Radio and Wireless Symposium, Orlando, US, January 2019.

Leave a Reply