The interest in reflectarray antennas has increased in recent years, due to the fact that this class of antennas is more cost-effective to manufacture, more compact and light weight compared to conventional high gain parabolic reflectors compared to standard phased arrays where feed network losses are significant. In its basic form, a microstrip reflectarray consists of a flat array of microstrip patches or dipoles printed on a thin, metal backed dielectric substrate, which is illuminated by a feed, typically a horn antenna. In general, the feed is positioned at an offset angle and the distance from the reflectarray surface is normally assumed to be far enough from the reflecting surface so that the incident field can be approximated by a plane wave.

In our previous publications, we introduced a new tuneable material, termed Electro-Chromic (EC) material, where we have shown that standard inorganic EC structures in the form of EC film/electrolyte/Ion storage films (such as WO3/LiNbO3/NiO) and advanced structures in the form of electrolyte/EC film/Ion storage/ electrolyte, such as LiNbO3/WO3/NiO/LiNbO3 films in addition to possessing reconfigurable optical properties also exhibit a degree of electric field induce dielectric tunability at radio frequencies. The extent of dielectric tunability in the standard EC structures is commensurate with the tunability exhibited by more mature bulk-tuneable technologies, such as Liquid Crystals (LCs), being between 5% and 20% depending on the frequency of operation, the thickness of the individual EC layers (EC films, electrolyte and ion tank), while the dielectric tunability of the advanced structures is as high as 65 % at 20 GHz.

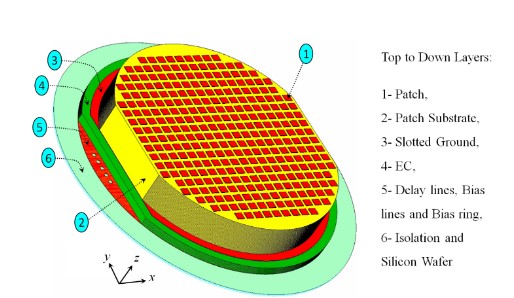

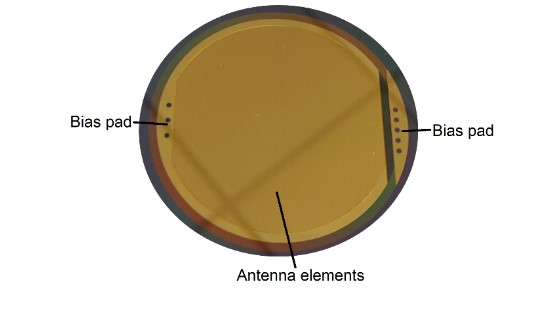

In this publication, we merge the attractive properties of EC material with the attractive characteristics of reflectarrays to create a beam reconfigurable reflect array. The fabricated reflectarray is made to operate at a centre frequency of 300 GHz and consists of over 13,000 antenna elements, Fig. 1. The presented work is supported by an analysis and full-wave simulations which consider the geometric and dielectric characteristics of the tunable EC material extracted from our previous work. In addition, the fabrication layout and bias scheme of the EC- based reflectarray elements is presented together with a discussion on the development of the process required to manufacture a representative antenna composed of identical unit cells.

Fig. 1 Reflectarray; Perspective view of designed reflectarray, not to scale (left) and fabricated reflectarray

Leave a Reply